We possess world-class, fully automated color coated aluminum coil production lines with an annual capacity of 200,000 tons, specializing in providing high-quality, multi-color coated aluminum solutions for building curtain walls, high-end home furnishings, and other fields.

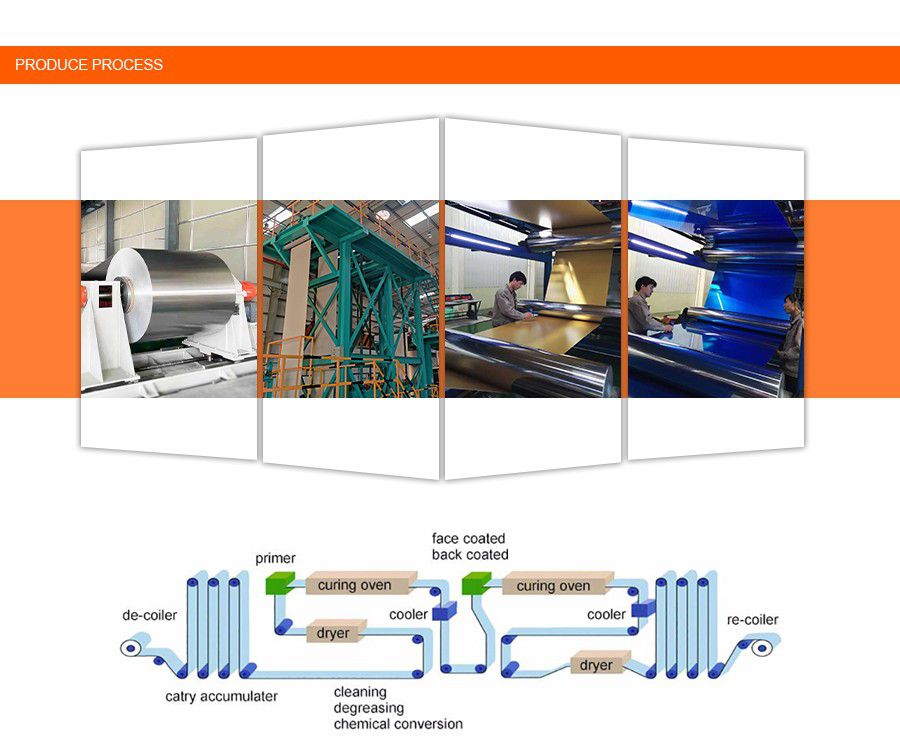

Production process

- Uncoiling and leveling equipment will uncoil and level the raw material aluminum coil for leveling treatment to ensure that the aluminum coil has excellent flatness, and then enter the cleaning equipment.

- Pickling improves the roughness of metal surfaces, making them easier to coat or paint. At the same time, pickling increases the hydrophilicity of the metal surface, which helps to achieve better adhesion to the surface.

- The purpose of alkaline cleaning is to remove oil, grease, dirt and other impurities from aluminum surfaces, while minimizing dust and rust on the surface. Ensure that the paint adheres better to the surface of the aluminum coil.

- Coating is an important part of the production of color coated aluminum coil, and its quality directly determines the quality of color coated aluminum coil.

-Coating is divided into three steps: primer, topcoat and protective paint. The first primer spraying, its main role is to enhance the adhesion of the coating; followed by top coat spraying, making the product surface finish and color uniformity better; and finally protective paint coating, improve the product's antioxidant, weather resistance and other physical properties.

- Coatings include: acrylic primer, polyester, polyurethane or fluorocarbon. The products are moldable, scratch-resistant, aesthetically pleasing, weather-resistant and paintable.

- Baking and curing is the final stage in the production of color coated aluminum coils, and its purpose is to reinforce the coating and increase the product's resistance to weathering, corrosion and other properties. Color coated aluminum coils are passed through a curing oven with the temperature set between 300 and 500 degrees Celsius.

- Quality control: The thickness of the coating is confirmed by the quality inspector, and the coating has no leakage problems.

- Coil winding is also a core part of production and requires attention to detail to ensure winding accuracy and coil quality.

Quality Check:

A comprehensive quality control system covering the entire process from raw material intake and real-time online monitoring (such as coating thickness and color) to final performance testing (adhesion and weather resistance).