Products

Haomei Aluminum CO., LTD.

Prepainted Metal Sheets

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H16, H24 etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

Colors : RAL or Pantone or Customized

Application : Roofing, composite panel, curtain wall, ce

Pre-painted sheet metal refers to metal sheets, typically made from materials like steel or aluminum, that have been coated with paint before being formed or processed into end products. This pre-coating process is often done through methods such as coil coating, where the metal is painted while in coil form, or through spray painting on flat sheets.

Pre-painted aluminum sheet metal is a versatile and efficient material choice for a variety of applications, combining aesthetic appeal with functional benefits. Its durability, cost-effectiveness, and ease of maintenance make it a popular option in construction, automotive, appliance manufacturing, and more.

The Specification of Prepainted Metal Sheets:

Aluminum Alloy: | 1050 1060 1100 3003 3004 3105 5005 5052 5754 8011 etc. |

Thickness: | 0.08-5.0mm |

Width: | <2650mm |

Coils Core Diameter: | 150mm, 405mm, 505mm, 508mm, 510mm |

Coating Thickness: | PVDF>=25micron, PE>=18micron |

Color Standard: | E < 2 or it is not obvious by eyeballing |

Pencil Hardness: | > 2HB |

Coating Adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

T Bend: | ≤ 2 T |

Boiling Point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, indoor deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

The Features of Pre painted Metal Sheets:

- Durability: The pre-painted finish is often more durable than post-painted surfaces, as it is baked on and adheres well to the aluminum, providing resistance to scratches, corrosion, and UV degradation.

- Aesthetic Variety: Pre-painted aluminum comes in a wide range of colors and finishes, including matte, gloss, and textured surfaces, allowing for greater design flexibility.

- Cost-Effectiveness: Pre-painting reduces the need for additional painting processes after fabrication, which can save time and labor costs.

- Environmental Considerations: Many pre-painted aluminum products utilize eco-friendly coatings and processes, which can lead to lower VOC emissions compared to traditional painting methods.

- Maintenance: Pre-painted aluminum surfaces are generally easier to clean and maintain compared to uncoated or post-painted surfaces.

The Application of Prepainted Sheet Metal:

Pre-painted sheet metal is widely used in various industries, including:

Construction: Building facades, roofing, and architectural panels.

Automotive: Trim and body panels.

Appliances: Refrigerator and washing machine exteriors.

Signage: Outdoor signs and displays.

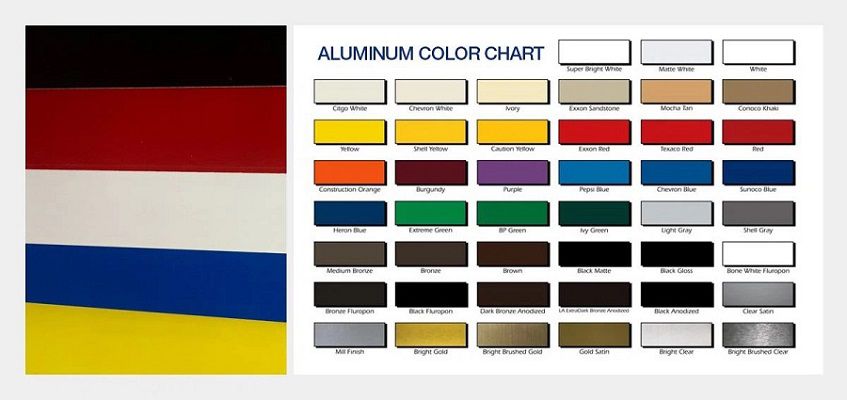

The Production Process of Pre painted Sheet Metal:

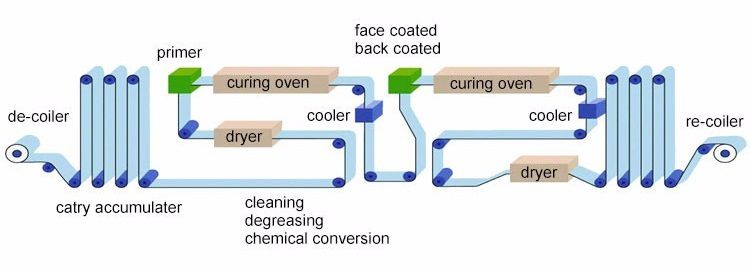

Package of Prepainted Metal Sheet:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.