Products

Haomei Aluminum CO., LTD.

Precoated Aluminium Sheet

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H24, etc.

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

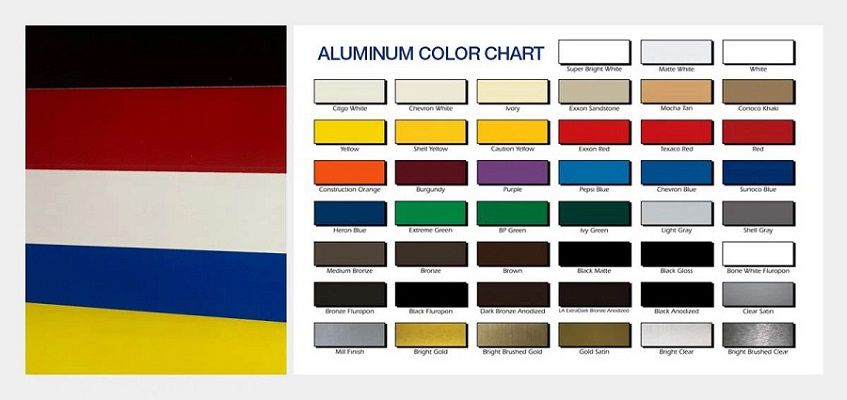

Colors : RAL or Pantone or Customized

Application : Roofing, composite panel, trailer, shutter, g

Precoated aluminium sheet refers to aluminum sheets that have been coated with a layer of paint or other protective finish before they are formed or fabricated into final products. This process enhances the aluminum's surface properties and provides a variety of benefits.

Pre coated aluminum panels have good fireproof, waterproof, sound insulation, heat insulation function and light weight, weather resistance, acid corrosion resistance, chalking resistance, decay resistance, resistance to ultraviolet irradiation, no discoloration and other advantages, and processing and installation is simple and fast.

Specification of Precoated Aluminium Sheet:

Alloy | Temper | Thickness (mm) | Width (mm) | Coil I.D. (mm) | Coating | Coating Thickness |

1100 1050 1060 1070 3003 3004 3005 3105 | H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38, H44, H46, H48 etc. | 0.2-1.2 | 10-1800 | 150/300/400/500/505/508 | PE/PVDF | One-Coat: 18+/-2um Two-Coat: 25-28um Back coat:5-10um |

Special specification could be customized. | ||||||

Features of Precoated Metal Sheet:

- Durability: The pre-coated finish is often more durable than post-painted surfaces, as it is baked on and adheres well to the aluminum, providing resistance to scratches, corrosion, and UV degradation.

- Aesthetic Variety: Pre-coated aluminum sheet comes in a wide range of colors and finishes, including matte, gloss, and textured surfaces, allowing for greater design flexibility.

- Cost-Effectiveness: Pre-coating reduces the need for additional painting processes after fabrication, which can save time and labor costs.

- Environmental Considerations: Many pre-coated aluminum products utilize eco-friendly coatings and processes, which can lead to lower VOC emissions compared to traditional painting methods.

- Maintenance: Pre-coated aluminum surfaces are generally easier to clean and maintain compared to uncoated or post-painted surfaces.

Application of Precoated Aluminum Sheet:

- Architectural decoration: used to make various special-shaped materials, panels, exterior panels and curtain wall panels, etc.

- Automobile manufacturing: used to make automobile body panels, interior panels, door panels, engine hoods and other parts.

- Medical equipment: used as packaging materials for medical instruments and equipment, as well as operating room isolation materials, medical consumables, etc.

- Home appliance manufacturing: used to make the shell and internal materials of household appliances such as televisions, refrigerators, and air conditioners.

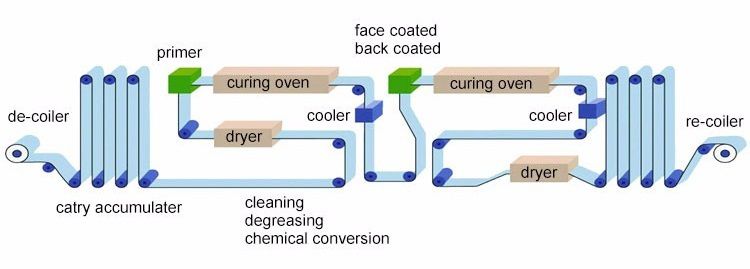

Production Process of Precoated Aluminium Sheet:

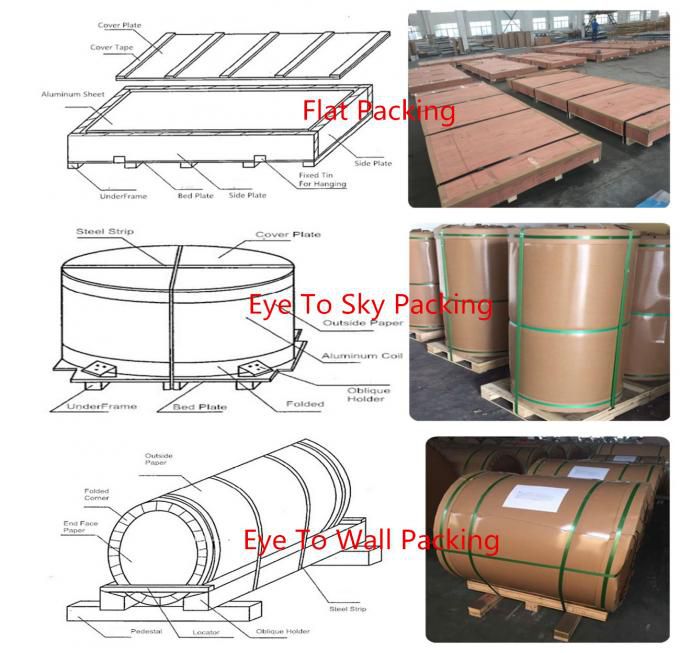

Package of Precoated Aluminum Sheet:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.