Products

Haomei Aluminum CO., LTD.

HDPE Coated Aluminum Coil

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H16, H24 etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : HDPE

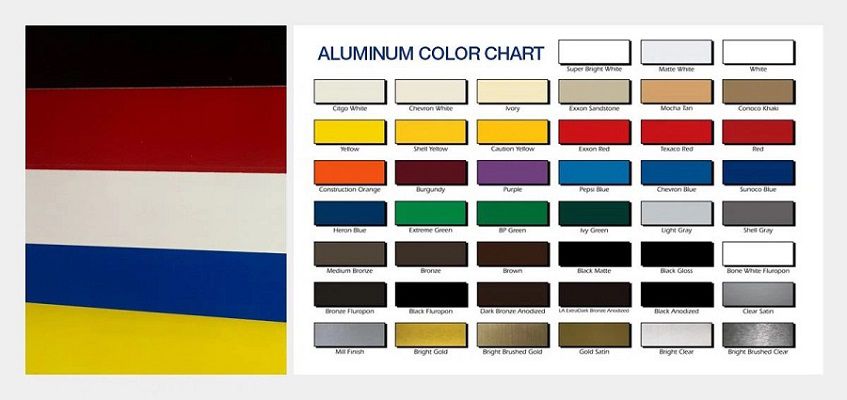

Colors : RAL or Pantone or Customized

Application : Roofing, composite panel, curtain wall, siding, ceiling, sh

HDPE coated aluminum coil is a type of aluminum coil that has been coated with a PVDF (Polyvinylidene fluoride) paint. This highly durable, weather-resistant coating is known for its high-quality finish, excellent adhesion, and resistance to fading, chalking and cracking.

HDPE coated aluminum coil is a popular material for architectural decoration, exterior cladding, and signage applications due to its vibrant colors, outstanding gloss, and long-lasting performance. PVDF paint is guaranteed about10-15 years.

With its long-lasting durability, HDPE coated aluminum coil is used in a variety of applications, including building facades, roofing systems, and interior decoration. The diversity in its finishes makes it a popular choice for architects and designers seeking to create unique and stunning buildings.

Specification of HDPE Coated Aluminum Coil:

Aluminum Alloy: | 1050 1060 1100 3003 3004 3105 5005 5052 5754 8011 etc. |

Thickness: | 0.08-5.0mm |

Width: | <2650mm |

Coils Core Diameter: | 150mm, 405mm, 505mm, 508mm, 510mm |

Coating Thickness: | PVDF>=25micron, PE>=18micron |

Color Standard: | E < 2 or it is not obvious by eyeballing |

Pencil Hardness: | > 2HB |

Coating Adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

T Bend: | ≤ 2 T |

Boiling Point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, indoor deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Features of HDPE Color Coated Aluminum Coil:

- High Durability: Our color coated aluminum coils are corrosion-resistant, ensuring a longer lifespan.

- Aesthetic Appeal: The wide range of colors and finishes enhances the visual appeal of your products.

- Environmental Friendly: Our products are eco-friendly and can be recycled.

- Easy Maintenance: Minimal maintenance is required to keep the coils in top condition.

- Customization: We offer customized solutions to meet specific project requirements.

Application of HDPE Coated Aluminum Sheet:

- Architectural decoration: used to make various special-shaped materials, panels, exterior panels and curtain wall panels, etc.

- Automobile manufacturing: used to make automobile body panels, interior panels, door panels, engine hoods and other parts.

- Medical equipment: used as packaging materials for medical instruments and equipment, as well as operating room isolation materials, medical consumables, etc.

- Home appliance manufacturing: used to make the shell and internal materials of household appliances such as televisions, refrigerators, and air conditioners.

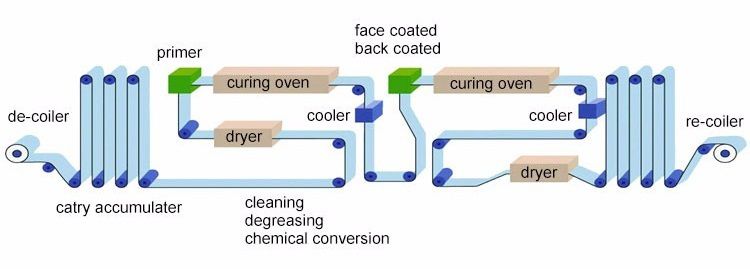

Production Process of HDPE Coated Aluminium Sheet:

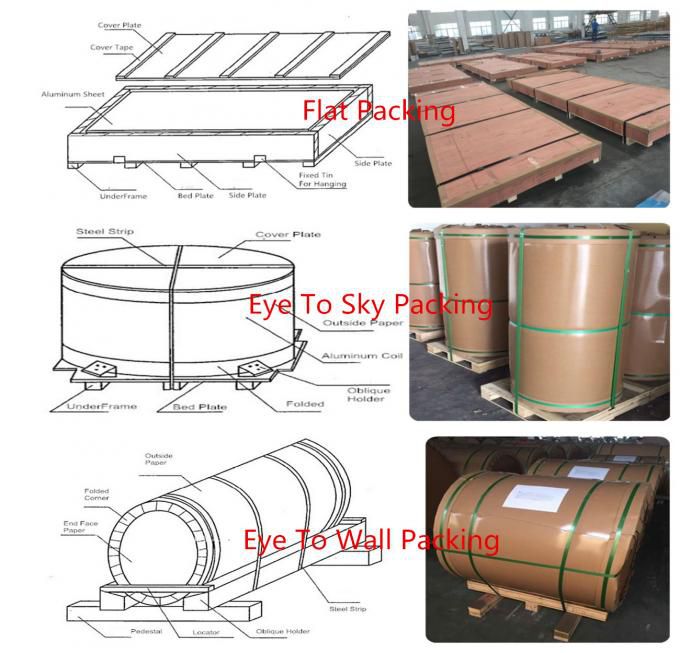

Package of HDPE Coated Aluminum Sheets:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.