Products

Haomei Aluminum CO., LTD.

Color Sheet Metal

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H24, etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

Colors : RAL or Pantone or Customized

Application : Roofing, curtain wall, ceiling, shutter, gutte

Color sheet metal usually refers to sheet or plate metal that has been color-coated. This material is used in a wide range of applications in the engineering, manufacturing and construction industries, especially where metal products are required for aesthetic appeal, durability and specific functionality. Colored coatings usually have some corrosion resistance and can extend the service life of coated sheet metal.

Specification of Color Sheet Metal:

Alloy | Temper | Thickness (mm) | Width (mm) | Coil I.D. (mm) | Coating | Coating Thickness |

1100 1050 1060 1070 3003 3004 3005 3105 | H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38, H44, H46, H48 etc. | 0.2-1.2 | 10-1800 | 150/300/400/500/505/508 | PE/PVDF | One-Coat: 18+/-2um Two-Coat: 25-28um Back coat:5-10um |

Special specification could be customized. | ||||||

Features of Colour Sheet Metal:

- Aesthetic Appeal: Available in a wide range of colors and finishes, allowing for creative design options.

- Durability: Coatings enhance the material’s resistance to corrosion, UV light, and wear, prolonging the lifespan of the aluminum.

- Low Maintenance: Color coated aluminum is generally easy to clean and maintain, making it suitable for various environments.

Application of Colour Metal Sheet:

- Architectural decoration: used to make various special-shaped materials, panels, exterior panels and curtain wall panels, etc.

- Automobile manufacturing: used to make automobile body panels, interior panels, door panels, engine hoods and other parts.

- Medical equipment: used as packaging materials for medical instruments and equipment, as well as operating room isolation materials, medical consumables, etc.

- Home appliance manufacturing: used to make the shell and internal materials of household appliances such as televisions, refrigerators, and air conditioners.

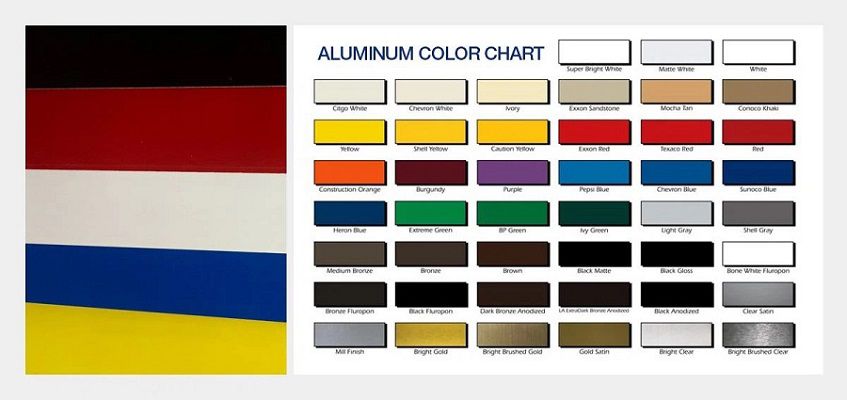

Production Process of Metal Colour Sheet:

- Raw material coil input: The unwinder continuously unwinds the coil to ensure that the coil is continuously and stably input into the production line.

- Surface cleaning and chemical treatment: Clean the upper and lower surfaces of the aluminum coil and perform chemical pretreatment to ensure that the paint can adhere firmly.

- Painting: Use a roller coater for painting, including at least two layers of topcoat and primer.

- Paint layer curing: The newly coated coil should be fixed before contacting the next roller to avoid mutual adhesion and damage.

- Finished product output: Ensure that the production line speed is synchronized with the transfer of the finished product coil to complete the finished product output.

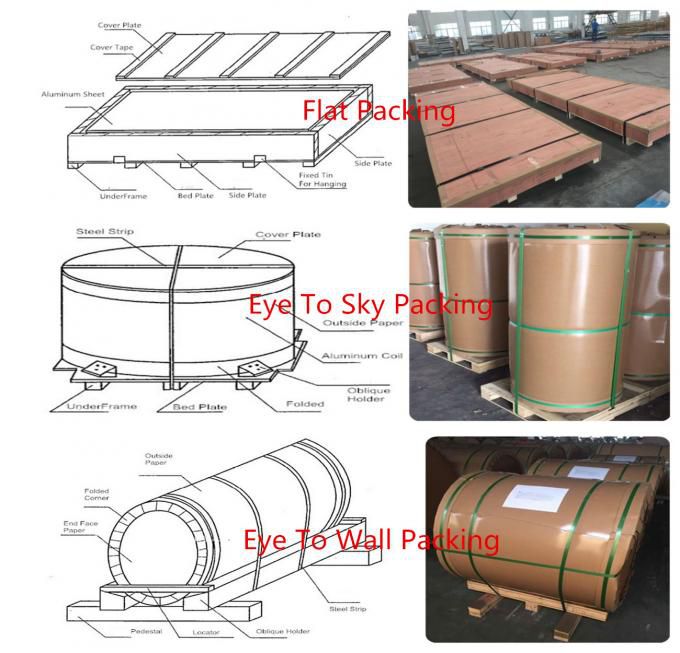

Package of Color Sheet Metal:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.