Products

Haomei Aluminum CO., LTD.

Color Coated Aluminum Coil

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H24, etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

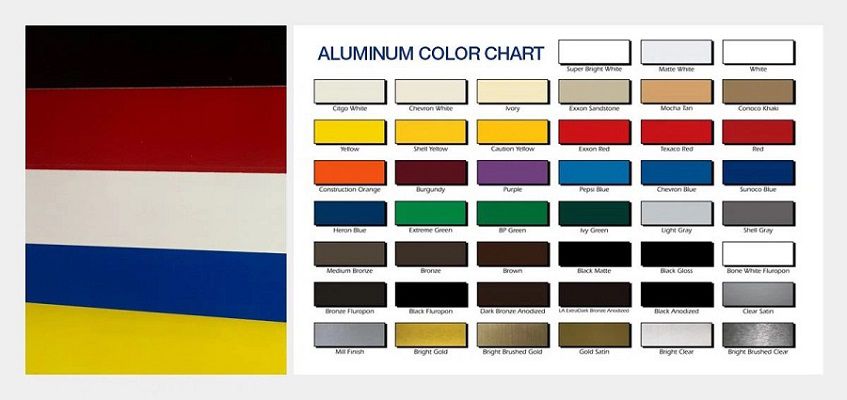

Colors : RAL or Pantone or Customized

Application : Roofing, curtain wall, ceiling, shutter, gutte

Color coated aluminum coil is an aluminum alloy coil as a substrate, after surface pretreatment (such as cleaning, oil removal, rust removal, etc.), coating application (such as spraying, roll coating, etc.), baking curing and other process steps, and finally formed a layer of uniform, continuous, dense color coating on the surface of aluminum coil.

Colour coated coil is treated with a special process, which has good weathering performance and can resist the erosion of the natural environment such as sunshine, rain, ice and snow.

Specification of Color Coated Aluminum Coil:

Aluminum Alloy: | 1050 1060 1100 3003 3004 3105 5005 5052 5754 8011 etc. |

Thickness: | 0.08-5.0mm |

Width: | <2650mm |

Coils Core Diameter: | 150mm, 405mm, 505mm, 508mm, 510mm |

Coating Thickness: | PVDF>=25micron, PE>=18micron |

Color Standard: | E < 2 or it is not obvious by eyeballing |

Pencil Hardness: | > 2HB |

Coating Adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

T Bend: | ≤ 2 T |

Boiling Point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, indoor deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

Features of Color Coated Aluminium Coil:

1. Small Density: The density of aluminum is only about one-third of steel. In the case of same thickness, calculate the final price on square meter basis, they are almost same.

2. Excellent Processability: Due to moderate structural strength of aluminum, it's easy for processing and convenient to installation, which can reduce construction cost.

3. Nice Decoration: Use aluminum for external insulation decoration, it have bright overall visual. With the addition of paint coating process, that make architectural appearance much more colorful and lively.

4. Long Period Of Validity: Because of the outstanding corrosion resistance, the period of validity can reach above 25 years under normal conditions.

5. High Recovery: The recovery rate can reach 85%.

Application of Color Coated Coil:

- Construction: Used for siding, roofing, gutters, and aluminum facades.

- Signage: Ideal for outdoor and indoor signage due to their vibrant colors and weather resistance.

- Home Appliances: Commonly found in the manufacturing of appliances like refrigerators and air conditioners.

- Automotive: Used in certain automotive parts for both functional and aesthetic purposes.

- Furniture: Employed in the design of modern furniture pieces.

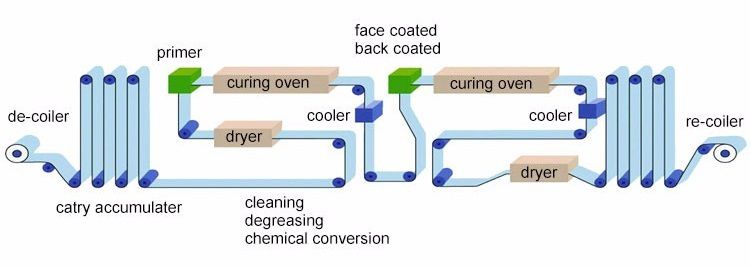

Production Process of Colour Coated Coil:

- Raw material coil input: The unwinder continuously unwinds the coil to ensure that the coil is continuously and stably input into the production line.

- Surface cleaning and chemical treatment: Clean the upper and lower surfaces of the aluminum coil and perform chemical pretreatment to ensure that the paint can adhere firmly.

- Painting: Use a roller coater for painting, including at least two layers of topcoat and primer.

- Paint layer curing: The newly coated coil should be fixed before contacting the next roller to avoid mutual adhesion and damage.

- Finished product output: Ensure that the production line speed is synchronized with the transfer of the finished product coil to complete the finished product output.

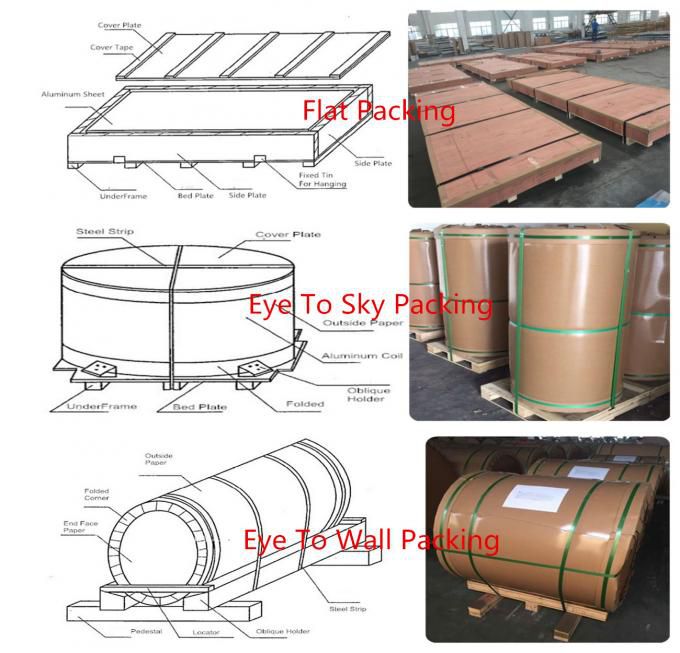

Package of Colour Coated Aluminium Coil:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.