Products

Haomei Aluminum CO., LTD.

Color Aluminum Coil

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H24, etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

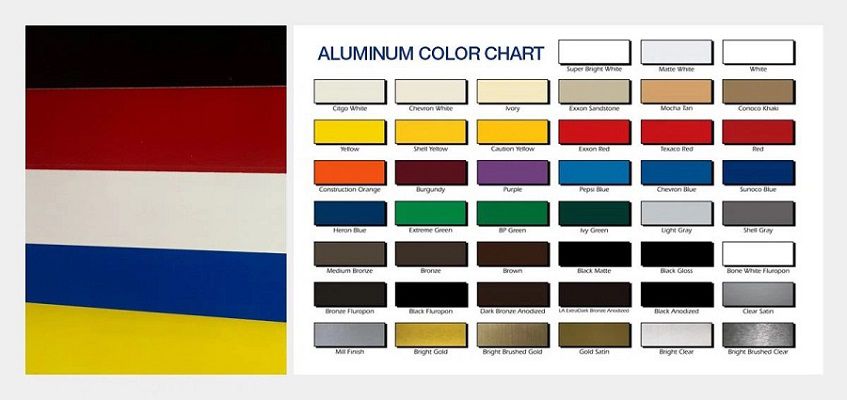

Colors : RAL or Pantone or Customized

Application : Roofing, curtain wall, ceiling, shutter, gutte

Color aluminum coils are aluminum rolls or strips that have been coated with a colored finish, typically using a process like coil coating or painting. These coils are widely used in various applications due to their aesthetic appeal, durability, and resistance to environmental factors.

Specification of Color Aluminum Coil:

Alloy | 1100 3003 5005 1050 1060 1070 3102 8011 3A21 3105 8079 |

Aluminum thickness | 0.1mm-3mm |

Aluminum max Width | 2200mm |

Coil’s standard diameter | interior diameter: 150mm, 405mm, 505mm |

Coating finish | PE, PVDF, PLOYESTER, ACRYLIC ACID |

MOQ | 5 tons per size |

Gloss | meet the customer’s requirement |

Total coating thickness | PVDF coating: more than 25 microns |

Coating adhesive | no lower than first grade |

Impact resistance | no cracking and peeling (50kg/cm, ASTMD-2794:1993) |

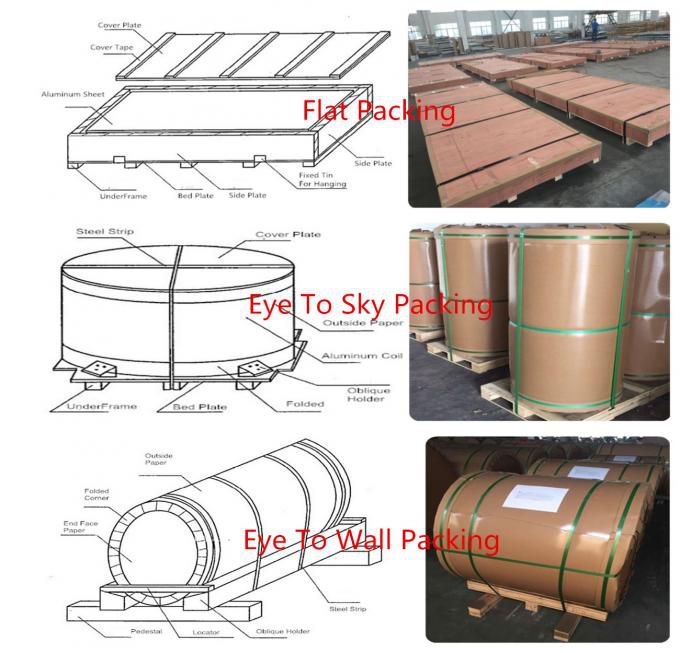

Outer packing | export standard, wooden pallet |

Features of Color Coil:

- High Gloss;

- Wide Range Of Color ;

- Good Mechanical Processing Performance;

- Impact And Weather Resistance;

- Easy For Processing And Installation;

- Excellent Torsion Strength.

Application of Colour Coil:

Application | Outdoor Applications | curtain wallboard, facades, solar collector, shutter doors, aluminum composite panel, roofing,gutter |

Indoor Applications | wall cladding, ceilings, bathrooms, kitchens and balconies, blinds,shutter doors, aluminum spacer | |

Advertisement and Market Applications | display platforms, signboards, fascia and shop fronts,license plate/name plate ,channel letter | |

Transportation | truck and container |

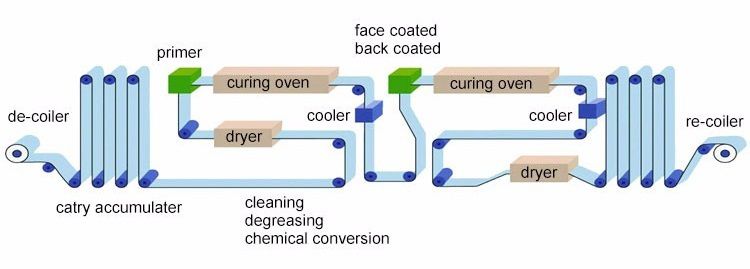

Production Process of Color Sheet Coil:

- Raw material coil input: The unwinder continuously unwinds the coil to ensure that the coil is continuously and stably input into the production line.

- Surface cleaning and chemical treatment: Clean the upper and lower surfaces of the aluminum coil and perform chemical pretreatment to ensure that the paint can adhere firmly.

- Painting: Use a roller coater for painting, including at least two layers of topcoat and primer.

- Paint layer curing: The newly coated coil should be fixed before contacting the next roller to avoid mutual adhesion and damage.

- Finished product output: Ensure that the production line speed is synchronized with the transfer of the finished product coil to complete the finished product output.

Package of Color Aluminum Coil:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.