Products

Haomei Aluminum CO., LTD.

Coated Sheet

Series : 1050, 1060, 1100, 3003, 3004, 3005 3105, 5005

Temper : H14, H24, etc

Thickness : 0.18 - 1.5 mm

Width : 10 - 2650 mm

Coating : PE, PVDF, HDPE, FEVE

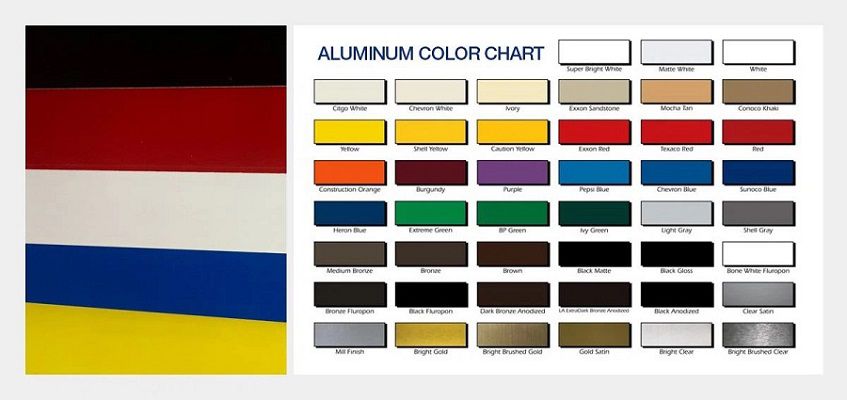

Colors : RAL or Pantone or Customized

Application : Roofing, curtain wall, ceiling, shutter, gutte

Coated sheets are available in a variety of specifications and colors on the market, and prices vary depending on factors such as manufacturers, specifications, quality, etc. Coated sheet metal is commonly used in various applications, including construction (windows, doors, facades), automotive parts, packaging materials, and consumer products due to its lightweight, strength, and versatility.

Specification of Coated Sheet:

Alloy | 1100 3003 5005 1050 1060 1070 3102 8011 3A21 3105 8079 |

Aluminum thickness | 0.1mm-3mm |

Aluminum max Width | 2200mm |

Coil’s standard diameter | interior diameter: 150mm, 405mm, 505mm |

Coating finish | PE, PVDF, PLOYESTER, ACRYLIC ACID |

MOQ | 5 tons per size |

Gloss | meet the customer’s requirement |

Total coating thickness | PVDF coating: more than 25 microns |

Coating adhesive | no lower than first grade |

Impact resistance | no cracking and peeling (50kg/cm, ASTMD-2794:1993) |

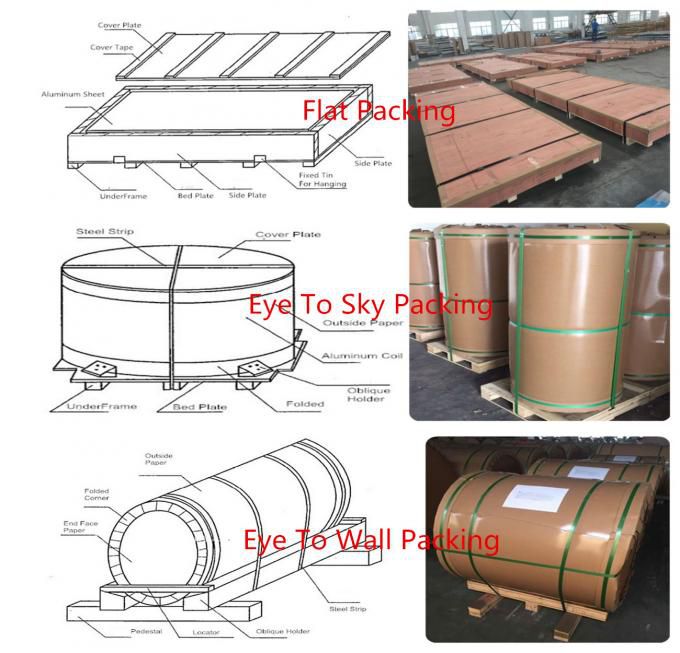

Outer packing | export standard, wooden pallet |

Features of Coated Plate:

- High Gloss;

- Wide Range Of Color ;

- Good Mechanical Processing Performance;

- Impact And Weather Resistance;

- Easy For Processing And Installation;

- Excellent Torsion Strength

Application of Coated Sheet Metal:

Coated sheet is widely used in various industries, including:

- Construction: Building facades, roofing, and architectural panels.

- Automotive: Trim and body panels.

- Appliances: Refrigerator and washing machine exteriors.

- Signage: Outdoor signs and displays.

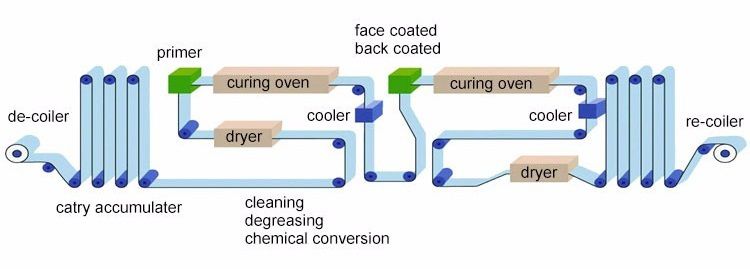

Production Process of Coated Metal Sheet:

- Raw material coil input: The unwinder continuously unwinds the coil to ensure that the coil is continuously and stably input into the production line.

- Surface cleaning and chemical treatment: Clean the upper and lower surfaces of the aluminum coil and perform chemical pretreatment to ensure that the paint can adhere firmly.

- Painting: Use a roller coater for painting, including at least two layers of topcoat and primer.

- Paint layer curing: The newly coated coil should be fixed before contacting the next roller to avoid mutual adhesion and damage.

- Finished product output: Ensure that the production line speed is synchronized with the transfer of the finished product coil to complete the finished product output.

Package of Coated Sheets:

ABOUT US

PRODUCTS

APPLICATION

CONTACT US

Mobile: +86-18137889531 (same number on WeChat)

Phone: +86-371-65621391

Email: nydia@aluminumhm.com

No.14 Waihuan Road, CBD,

Zhengzhou, China

Copyright © 2026 Haomei Aluminum CO., LTD.